SEALXTREME LEAK REPAIR KIT

Home / Products / C-SMARTSEAL / SEALXTREME Leak Repair Kit

SEALXTREME LEAK REPAIR KIT

SEALXTREME Leak Repair Kit seals leak found on the pipe under 30 minutes when pipe medium is drained with no pressure. The maximum post-cure pressure SEALXTREME Leak Repair Kit can withstand is approximately 28 bar (406 psi). This is a specially formulated wrap repair kit that is durable and cost-effective to seal pipe leaks with high industrial strength

FEATURES

-

Withstand pressure up to 28 bar (406 psi) post cure

-

Withstand temperature up to 120 °C (248 °F) post cure

-

Fix leaks in less than 30 minutes

-

Hand-Applied

-

Works on both metal and non-metal pipes

-

Enhance chemical resistance

-

Repair and extend pipe life

-

Environmentally friendly, reduce carbon footprint

PACKAGING INFORMATION

ITEM CODE | SIZE | IMPA CODE | HS CODE |

|---|---|---|---|

SNLRK0206 | 50 mm x 1.8 m | 812173 | 39191099 |

SNLRK0309 | 75 mm x 2.7 m | 812452 | 39191099 |

SNLRK0412 | 100 mm x 3.6 m | 812174 | 39191099 |

GUIDELINES FOR BEST PRACTICE

PIPE DIAMETER (mm) | PIPE DIAMETER (inch) | KIT SIZE FOR PRESSURE UPTO 4 bar (50 psi) | QUANTITY FOR PRESSURE UPTO 4 bar (50 psi) | KIT SIZE FOR PRESSURE UPTO 10 bar (150 psi) | QUANTITY FOR PRESSURE UPTO 10 bar (150 psi) |

|---|---|---|---|---|---|

15 mm | ½ inch | 50 mm x 1.8 m | 1 | 50 mm x 1.8 m | 1 |

20 mm | ¾ inch | 50 mm x 1.8 m | 1 | 50 mm x 1.8 m | 1 |

25 mm | 1 inch | 50 mm x 1.8 m | 1 | 50 mm x 1.8 m | 2 |

32 mm | 1¼ inch | 50 mm x 1.8 m | 1 | 50 mm x 1.8 m | 3 |

40 mm | 1½ inch | 50 mm x 1.8 m | 2 | 50 mm x 1.8 m | 3 |

50 mm | 2 inch | 75 mm x 2.7 m | 1 | 75 mm x 2.7 m | 1 |

65 mm | 2½ inch | 75 mm x 2.7 m | 1 | 75 mm x 2.7 m | 2 |

80 mm | 3 inch | 75 mm x 2.7 m | 1 | 100 mm x 3.6 m | 2 |

100 mm | 4 inch | 75 mm x 2.7 m | 1 | 100 mm x 3.6 m | 3 |

125 mm | 5 inch | 100 mm x 3.6 m | 2 | 100 mm x 3.6 m | 3 |

150 mm | 6 inch | 100 mm x 3.6 m | 2 | 100 mm x 3.6 m | 4 |

200 mm | 8 inch | 100 mm x 3.6 m | 2 | 100 mm x 3.6 m | 5 |

250 mm | 10 inch | 100 mm x 3.6 m | 3 | 100 mm x 3.6 m | 6 |

300 mm | 12 inch | 100 mm x 3.6 m | 4 | 100 mm x 3.6 m | 8 |

350 mm | 14 inch | 100 mm x 3.6 m | 4 | 100 mm x 3.6 m | 8 |

400 mm | 16 inch | 100 mm x 3.6 m | 5 | 100 mm x 3.6 m | 9 |

450 mm | 18 inch | 100 mm x 3.6 m | 5 | 100 mm x 3.6 m | 9 |

FOR SIZES ABOVE 450 mm (18 inch), contact us

TECHNICAL DATA

PARAMETER | VALUE |

|---|---|

Tensile Strength | 1655 bar (24000 psi) |

Lap Shear Strength | 62 bar (900 psi) |

Flexural Strength | 1103 bar (16000 psi) |

Application Temperature | 0 °C to 65 °C (32 °F to 149 °F) |

Dielectric Strength | 16000 Volts |

Hardness | 85 Shore D |

Service temperature | -50 °C to 120 °C (-58 °F to 248 °F) |

Design Pressure | 28 bar (406 psi) |

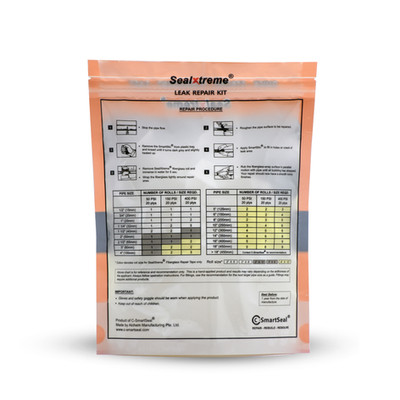

USAGE INSTRUCTIONS

-

Safety first, wear appropriate protective gear. Gloves are a must

-

Knead the epoxy stick until 80% harden

-

Use the 80% cure epoxy stick to seal the leak location

-

Dip the fiberglass repair tape in water for 5 seconds

-

Reinforce repair area with fiberglass repair tape

-

Polish the surface of fiberglass repair tape with water and rub in parallel direction with the pipe